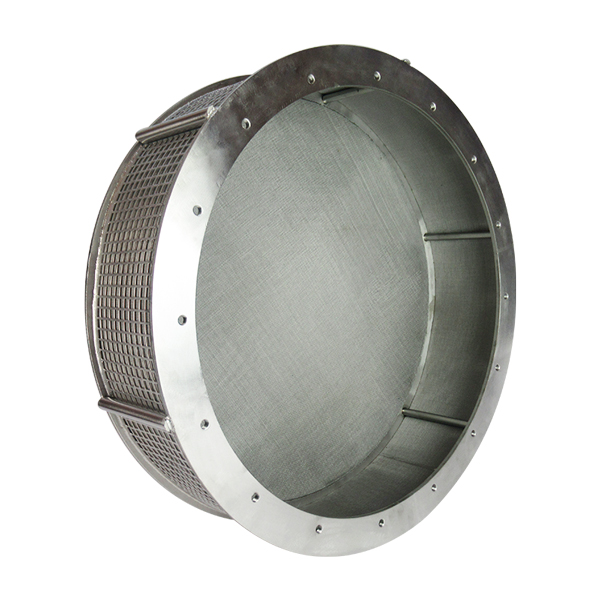

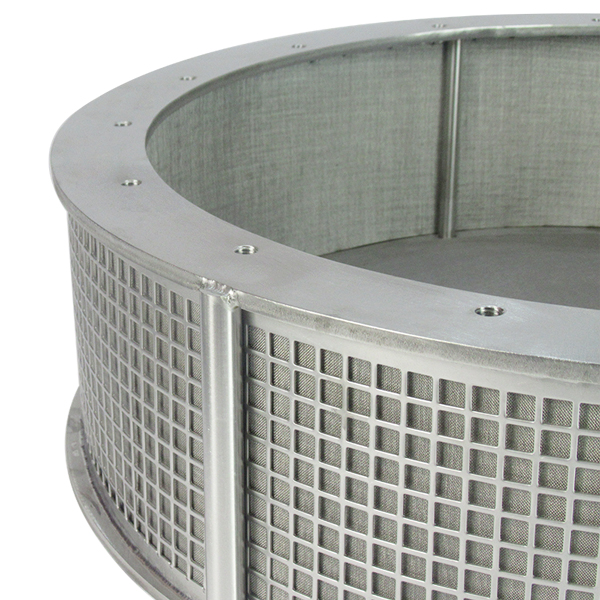

200μm Sintered Mesh Filter Element

Product SpecificationsHuahang

Type |

Sintered mesh filter element |

Dimension |

530x624x161 |

Material |

Stainless steel mesh |

Pore size |

200μm |

Product featuresHuahang

1. High strength and good rigidity: it has high mechanical strength and compressive strength, good processing, welding and assembly performance, and is easy to use.

2. Uniform and stable precision: achieving uniform and consistent filtering performance for all filtering accuracies, with no change in mesh size during use

3. Widely used in various environments: can be used for filtration in temperature environments ranging from -200C to 650C, as well as acidic and alkaline environments.

4. Excellent cleaning performance: The countercurrent cleaning effect is excellent, can be reused, and has a long service life (can be cleaned using methods such as countercurrent water, filtrate, ultrasound, melting, baking, etc.)

ApplicationHuahang

1. Precision filtration of various hydraulic and lubricating oils in the mechanical industry

2. The filtration and purification of various polymer melts in the chemical fiber film industry, the filtration of high-temperature and corrosive liquids in the petrochemical industry, and the filtration, washing, and drying of materials in the pharmaceutical industry.

3. The application of gas homogenization in the powder industry and fluidization plates in the steel industry.

4. The splitter and other components in explosion-proof electrical appliances.

5. Fluidization and dense phase conveying systems for coal injection in blast furnaces

6. Catalyst support grille.

7. Gas solid, liquid solid, and gas liquid separation.

Shay

Shay