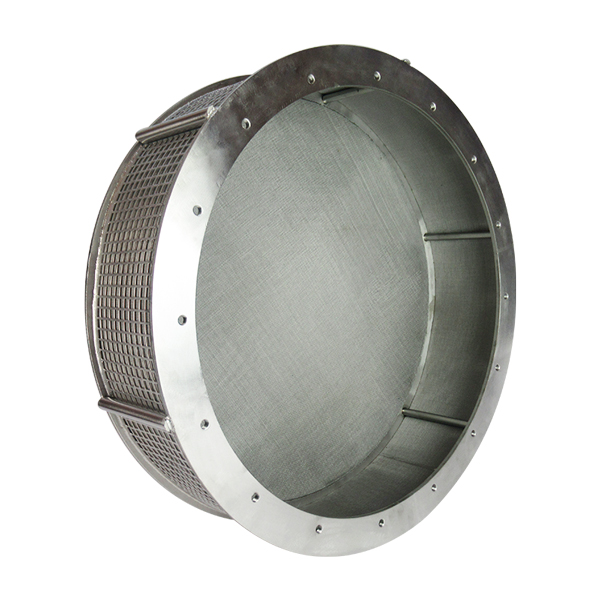

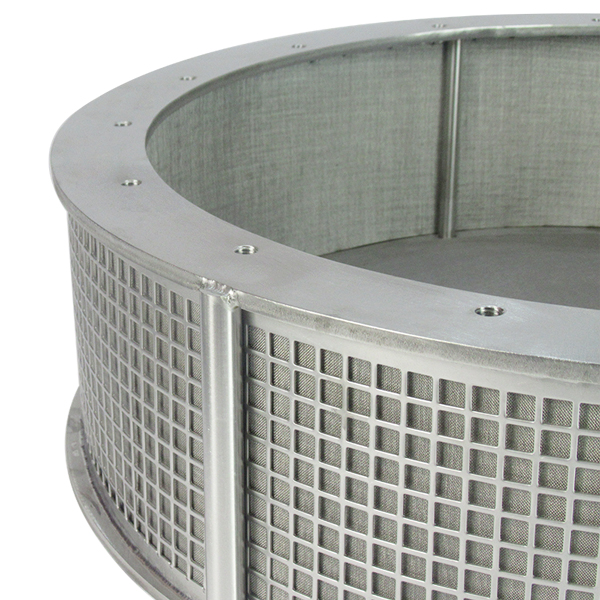

200μm Sintered Mesh Element Element

Litlhaloso tsa SehlahisoaHuahang

Mofuta | Sintered mesh filter element |

Boemo | 530x624x161 |

Lintho tse bonahalang | Mesh ea tšepe e sa hloekang |

Boholo ba pore | 200μm |

Likarolo tsa sehlahisoaHuahang

1. Matla a phahameng le ho tiea ho hotle: e na le matla a phahameng a mochine le matla a hatellang, ts'ebetso e ntle, ts'ebetso ea welding le kopano, 'me e bonolo ho e sebelisa.

2. Ho nepahala ka mokhoa o ts'oanang le o tsitsitseng: ho finyella ts'ebetso e ts'oanang le e tsitsitseng ea ho sefa bakeng sa lintlha tsohle tse nepahetseng tsa ho sefa, ntle le phetoho ea boholo ba mesh nakong ea tšebeliso.

3. E sebelisoa haholo libakeng tse sa tšoaneng: e ka sebelisoa bakeng sa ho hloekisa libakeng tsa mocheso ho tloha ho -200C ho ea ho 650C, hammoho le libaka tse nang le acidic le alkaline.

4. Ts'ebetso e ntle ea ho hloekisa: Phello ea ho hloekisa ha countercurrent e ntle haholo, e ka sebelisoa hape, 'me e na le bophelo bo bolelele ba ts'ebeletso (e ka hloekisoa ho sebelisoa mekhoa e kang countercurrent water, filtrate, ultrasound, melting, baking, joalo-joalo).

KopoHuahang

1. Ho hloekisa ka mokhoa o nepahetseng oa oli e fapaneng ea hydraulic le lubricating indastering ea mechine

2. Ho hloekisoa le ho hloekisoa ha li-polymer tse fapa-fapaneng ho qhibiliha indastering ea lifilimi tsa lik'hemik'hale, ho hloekisoa ha metsi a mocheso o phahameng le a senyang indastering ea petrochemical, le ho hloekisa, ho hlatsoa le ho omisoa ha thepa indastering ea meriana.

3. Tšebeliso ea homogenization ea khase indastering ea phofo le lipoleiti tsa fluidization indastering ea tšepe.

4. Sekhahla le likarolo tse ling tsa lisebelisoa tsa motlakase tse thibelang ho phatloha.

5. Fluidization le tsamaiso e teteaneng ea ho tsamaisa karolo bakeng sa ente ea mashala ka har'a libopi tse phatlohang

6. Catalyst tšehetso grille.

7. Karohano e tiileng ea khase, e tiileng ea metsi, le karohano ea mokelikeli oa khase.

Shay

Shay