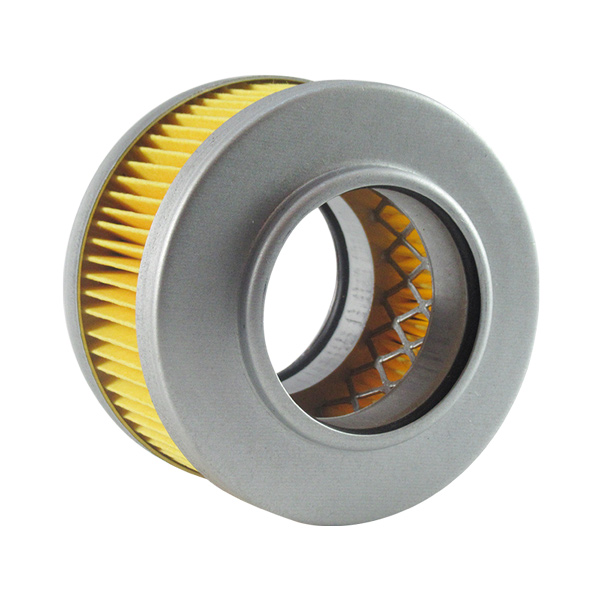

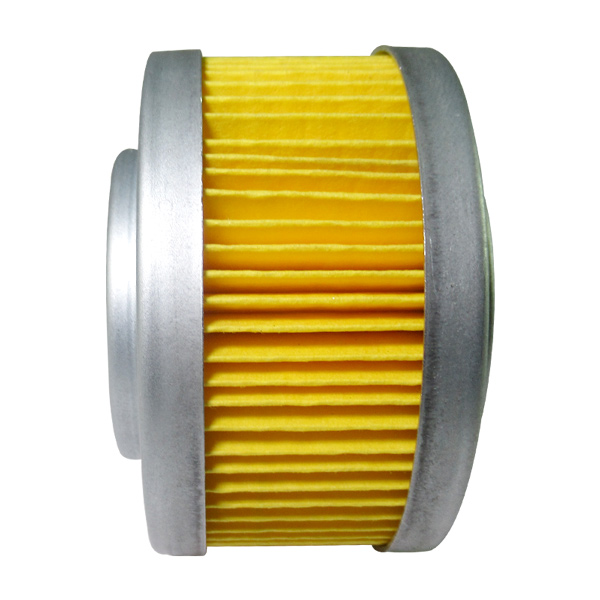

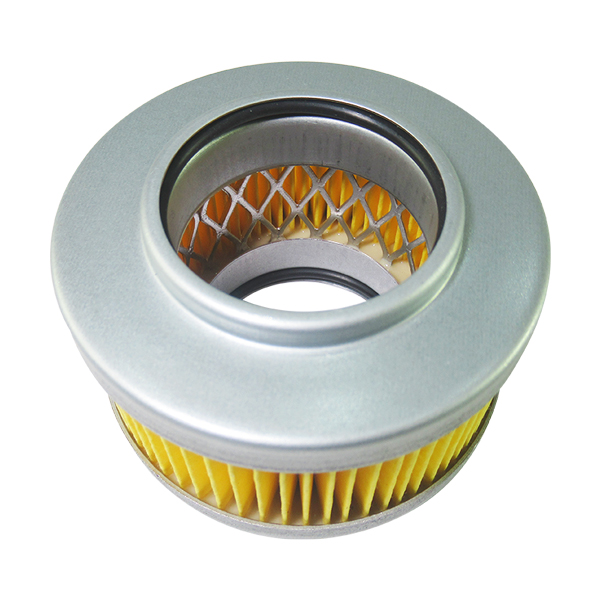

Custom Paper Oil Filter Element 79x54

Product SpecificationsHuahang

Dimension |

79x54 |

Media |

Filter paper |

End caps |

Carbon steel |

Inner skeleton |

Zinc infiltrated diamond mesh |

Sealing ring |

NBR |

MAINTENANCE METHODSHuahang

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

1. Before replacing, drain the original hydraulic oil, check the return oil filter element, suction oil filter element, and pilot filter element to see if there are iron, copper, or other impurities attached. If there are any, there may be hydraulic component faults. After troubleshooting, clean the system.

When changing hydraulic oil, all hydraulic oil filter elements (return oil filter element, suction oil filter element, pilot filter element) must be replaced at the same time, otherwise it is equivalent to not being replaced.

3. Identify the hydraulic oil grade. Different grades and brands of hydraulic oil should not be mixed, which may react and deteriorate to produce flocculent substances. It is recommended to use the designated oil for this excavator.

4. Before refueling, it is necessary to install the oil suction filter element. The pipe mouth covered by the oil suction filter element directly leads to the main pump. If impurities enter, it will accelerate the wear of the main pump, and if it is severe, it will start the pump.

5. Add oil to the standard position. Generally, there is an oil level gauge on the hydraulic oil tank. Check the level gauge. Pay attention to the parking method, generally all cylinders are fully retracted, that is, the forearm and bucket are fully extended and landed.

6. After refueling, be sure to exhaust the air from the main pump. Otherwise, there may be temporary inactivity of the entire vehicle, abnormal noise (air explosion) from the main pump, or damage to the main pump due to air pockets. The air exhaust method is to directly loosen the pipe joint at the top of the main pump and fill it up.

1. Efficient filtration: Fiberglass filters have very small pore sizes, which can filter out small particles and impurities in water, greatly improving water quality.

2. Chemical corrosion resistance: Fiberglass filters have characteristics such as acid resistance, alkali resistance, and high temperature resistance, and can also be used normally in chemical environments.

3. Long service life: Fiberglass filters usually have a longer service life than ordinary filters, usually reaching more than six months.

4. Easy to maintain: The maintenance of fiberglass filter is relatively simple, only requiring regular cleaning or replacement, and the maintenance cost is relatively low.

APPLICATION AREAHuahang

1. Used for filtering hydraulic systems of steel mills and continuous casting machines, as well as filtering various lubrication equipment.

2. Petrochemical: separation and recovery of products and intermediate products in refining and chemical production processes, purification of liquids, purification of magnetic tapes, optical discs, and photographic films in manufacturing, and filtration of oilfield injection water and natural gas particles.

3. Textile: Purification and uniform filtration of polyester melt during drawing process, protective filtration of air compressor, and oil and water removal of compressed gas.

4. Electronics and pharmaceuticals: pre-treatment filtration of reverse osmosis water and deionized water, pre-treatment filtration of detergent and glucose.

5. Mechanical processing equipment: lubrication systems and compressed air for papermaking machinery, mining machinery, injection molding machines, and large precision machinery

Purification, dust recovery and filtration of tobacco processing equipment and spraying equipment.

6. Railway internal combustion engines and generators: filtration of lubricating oil and engine oil.

7. Various hydraulic oil filters for automotive engines and engineering machinery, ships, and heavy-duty vehicles

1. Home: Fiberglass filter is suitable for water purifiers, water dispensers, and other equipment in homes. It can filter out small particles, residual chlorine, odors, and other pollutants in water, improving the quality of drinking water.

2. Industry: Fiberglass filters are widely used in industrial fields such as water treatment, wastewater treatment, and high-purity water preparation, and can remove various pollutants from water.

3. Medical: Fiberglass filters are also suitable for use in the medical field, such as operating room purification and laboratory water purification in hospitals.

Shay

Shay