0102030405

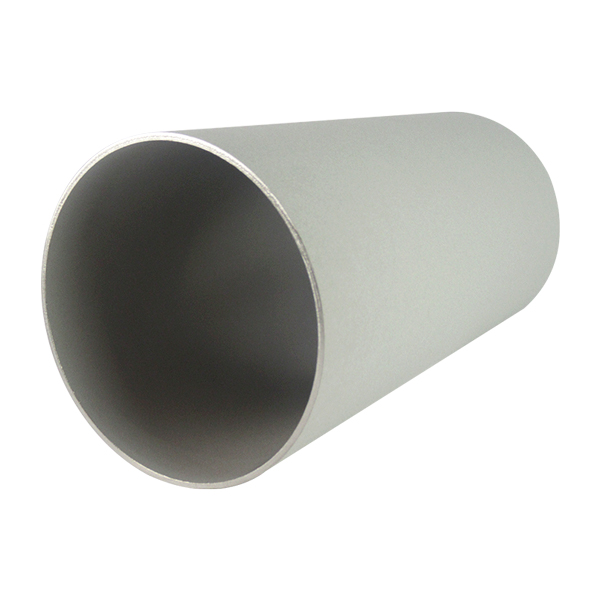

316L Sintered Powder Filter Element 3μm

Product SpecificationsHuahang

Type |

Sintered powder filter element |

Dimension |

200x400 |

Material |

316L |

Filtration accuracy |

3μm |

Product featuresHuahang

1) Stable shape, superior to other metal filter materials in terms of impact resistance and alternating load capacity;

2) Breathability, stable separation effect;

3) Excellent mechanical strength, suitable for use in high temperature, high pressure, and highly corrosive environments;

4) Especially suitable for high-temperature gas filtration;

5) Various shapes and precision products can be customized according to user requirements, and various interfaces can also be matched through welding.

NoteHuahang

1) Powder quality control: Strictly control the quality of stainless steel powder to avoid impurities and non-metallic inclusions, in order to prevent negative effects on product performance;

;

2) Processing process control: Control the sintering temperature, pressure, time and other process parameters to ensure the smooth formation and sintering process of stainless steel powder, and achieve the required material density and mechanical properties

;

3) Sealing and anti oxidation treatment: Stainless steel powder is susceptible to oxidation during processing, so appropriate measures need to be taken for sealing and anti oxidation treatment to ensure the quality and performance of the powder;

Sealing and anti oxidation treatment: Stainless steel powder is susceptible to oxidation during processing, so appropriate measures need to be taken for sealing and anti oxidation treatment to ensure the quality and performance of the powder

;

4) Reasonable mold design: Design a reasonable mold based on the shape and size requirements of the product, and ensure uniform filling and exhaust inside the mold to obtain high-quality molded parts

.

Shay

Shay