Stainless Steel Oil Filter Element 32x350

Product SpecificationsHuahang

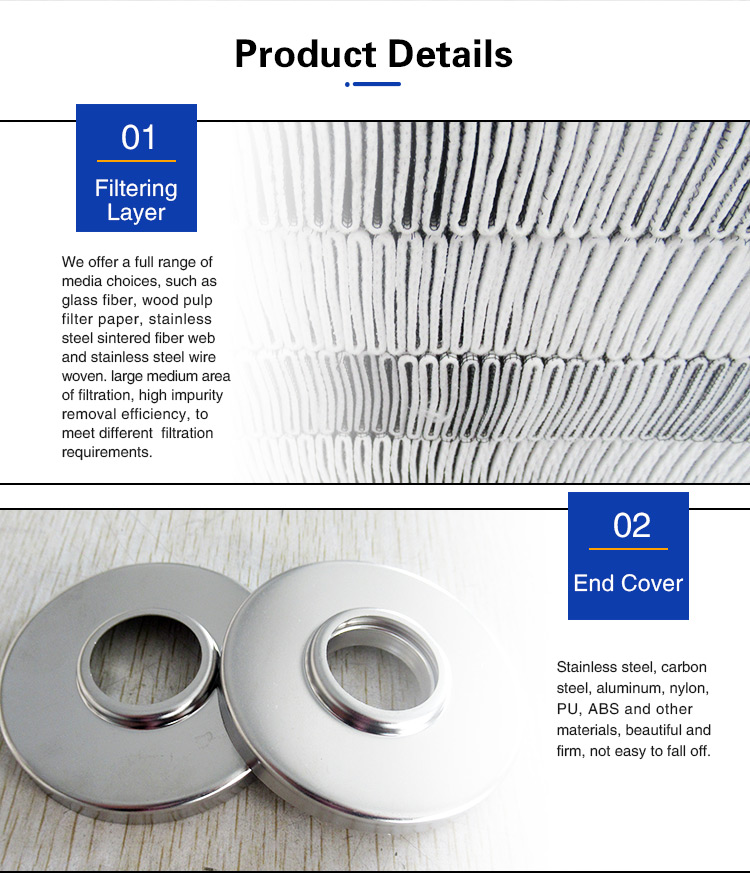

Filtration accuracy |

1~25μm |

Filter layer |

Stainless steel mesh |

Dimension |

32x350 |

End caps |

304/316 |

ADVANTAGESHuahang

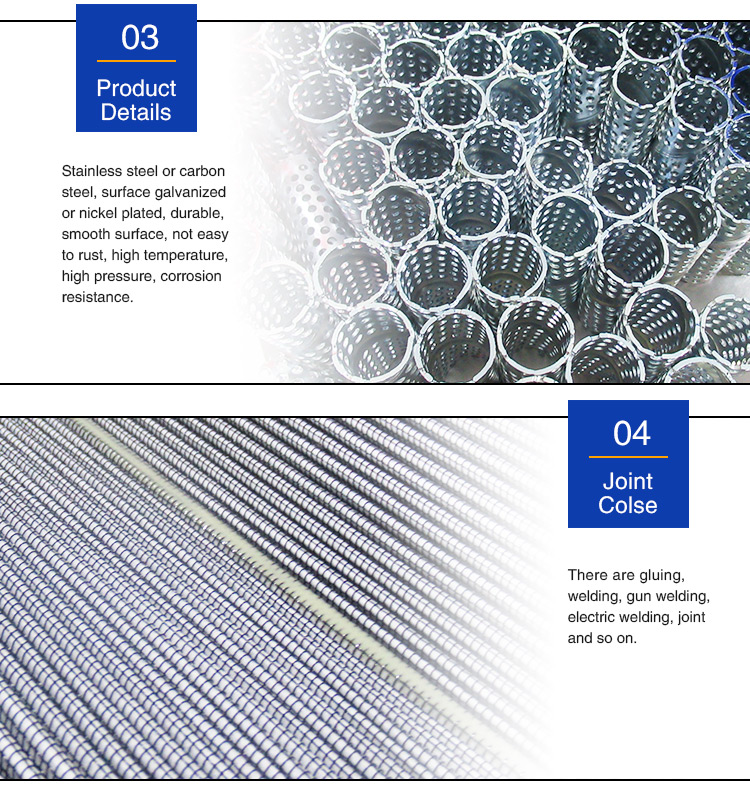

1. Good filtration performance and uniform surface filtration performance can be achieved with a filtration particle size of 2-200um;

2. Good corrosion resistance, heat resistance, pressure resistance, and wear resistance; It can be repeatedly rinsed and has a long service life.

3. Uniform and precise filtration accuracy of stainless steel filter pores;

4. The stainless steel filter element has a large flow rate per unit area;

5. Stainless steel filter element is suitable for low and high temperature environments;

6. After cleaning, it can be reused without replacement.

Washing methods

HUAHANG

1. Backwash cleaning method

The stainless steel filter element gradually increases the amount of retained material during use, causing the pressure difference before and after the filter to increase until it becomes clogged. When the filter is affected by the retention of excessive impurities, it can be cleaned by backwashing. By using reverse water inflow, the intercepted substances adhering to the surface of the filter element are peeled off and carried away by the backwash water flow, which is beneficial for removing sediment, suspended solids, etc. in the filter layer, and preventing the filter material from becoming clogged, so as to fully restore its interception ability and achieve the purpose of cleaning. The backwash cycle is generally one to four days.

2. Acid cleaning method

Dissolve potassium dichromate or crystals in water to 60 to 80 degrees, and slowly add concentrated sulfuric acid with a concentration of 94% until sufficient. Add slowly and stir. Add up to 1200 milliliters of potassium sulfate or completely dissolve, and the solution will appear dark red in color. At this time, the rate of adding concentrated sulfuric acid can be accelerated until it is completely added. If there are still undissolved crystals after adding concentrated sulfuric acid, they can be heated until dissolved. The function of cleaning solution is to remove general pollutants, grease, and metal particle impurities on the wall of stainless steel filter cartridge, and it can effectively kill the bacteria and microorganisms that grow on the filter cartridge and damage the heat source. If the filter element has been alkaline washed before, the alkaline solution must be washed first, otherwise fatty acids will precipitate and contaminate the filter element.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

faqHuahang

Shay

Shay