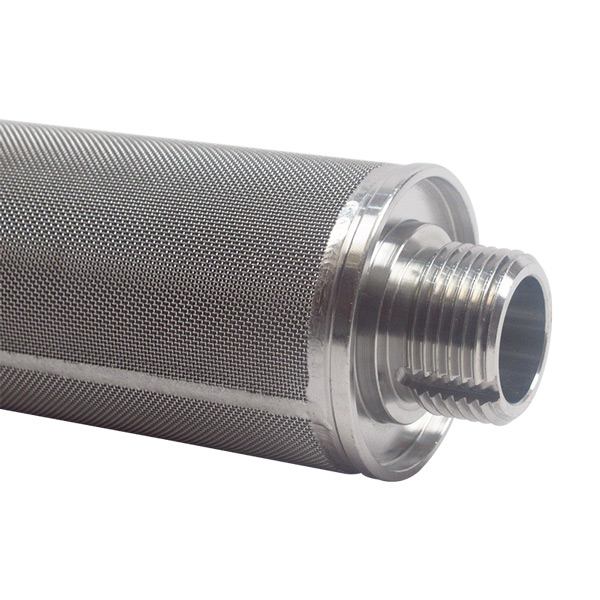

Sintered Felt Filter Element 47.5x218

Product SpecificationsHuahang

Dimension |

47.5x218 |

Filter layer |

Sintered felt |

Type |

Sintered filter element |

Interface |

External thread interface |

Filtration accuracy |

1~25μm |

featuresHuahang

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

- High heat and corrosion resistance: Work temperature resistance can reach 1000 °C, and stainless steel or alloy for corrosive application, which non-metallic textile, ceramic or polymer product can not compete.

- High porosity: It performs with up to 85% high porosity, long on-stream lifetime, high flow rates.

- Low pressure drop: The high porosity allows a very low pressure drop, lower energy cost at the same time.

- Depth filtration: It enables you to achieve high efficient result through surface filtration and its high dirt capacity offers depth particles capture.

- Enhanced gel removal: Addition of metal fiber felt enhances gel removal property of sintered filter media and eliminates fiber breaks during spinning.

- Longer life: Stainless steel fiber felt is added into sintered filter media, onstream life can be increased by a factor of two to three times that of conventional wire mesh media.

1. Efficient filtration: Fiberglass filters have very small pore sizes, which can filter out small particles and impurities in water, greatly improving water quality.

2. Chemical corrosion resistance: Fiberglass filters have characteristics such as acid resistance, alkali resistance, and high temperature resistance, and can also be used normally in chemical environments.

3. Long service life: Fiberglass filters usually have a longer service life than ordinary filters, usually reaching more than six months.

4. Easy to maintain: The maintenance of fiberglass filter is relatively simple, only requiring regular cleaning or replacement, and the maintenance cost is relatively low.

APPLICATION AREAHuahangHuahang

- Polymer filtering.

- Filtration of high temperature and corrosive liquid in oil refinery, chemical fields.

- Gas, water, printing ink filtering.

- Viscose rayon filtering.

- Filtration of hydraulic and lubricating oil in various equipment.

- Dust collection for high temperature gas.

- Support for filter media and carrier for catalyst.

- Material: 316-L stainless steel, 316 stainless steel , 304 stainless steel, nickel.

- Absolute filter rating: For liquids - 1µm to 80µm, for air and gases - below 0.1 µm is possible.

- Standard size: 500 mm × 1000 mm, 600 mm × 1000 mm, 600 mm × 1200 mm, 1000 mm × 1000 mm, 1000 mm × 1200 mm, 1000 mm × 1480 mm, 1180 mm × 1450 mm, 1180 mm × 1500 mm.

- Maximum size: 1500 mm × 1800 mm.

2) Standard specification size: 1200 * 1000 * 1.7mm;

3) The filtering accuracy is 2-300um.

1. Home: Fiberglass filter is suitable for water purifiers, water dispensers, and other equipment in homes. It can filter out small particles, residual chlorine, odors, and other pollutants in water, improving the quality of drinking water.

2. Industry: Fiberglass filters are widely used in industrial fields such as water treatment, wastewater treatment, and high-purity water preparation, and can remove various pollutants from water.

3. Medical: Fiberglass filters are also suitable for use in the medical field, such as operating room purification and laboratory water purification in hospitals.

Shay

Shay