0102030405

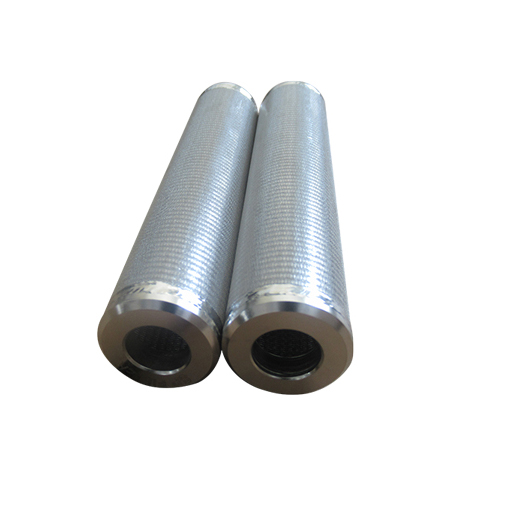

Customized Sintered Mesh Filter Element

Product SpecificationsHuahang

Type |

Sintered mesh filter element |

Dimension |

Customized |

Material |

Sintered mesh |

Filtration accuracy |

2~200μm |

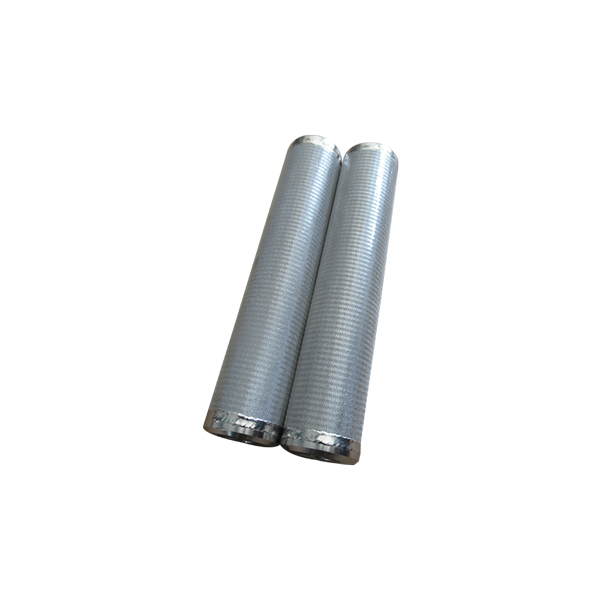

Product featuresHuahang

1) The standard five layer network is composed of a protection layer, a precision control layer, a dispersed layer, and a multi-layer reinforcement layer;

2) High strength: After sintering with five layers of wire mesh, it has extremely high mechanical strength and compressive strength;

3) High precision: It can achieve uniform surface filtration performance with a filtration particle size of 2-200um;

4) Heat resistance: can withstand continuous filtration from -200 ° C to up to 650 ° C;

5) Cleanability: Due to the surface filtration structure with excellent countercurrent cleaning effect, the cleaning is simple.

Application AreaHuahang

1) Used as a dispersed cooling material in high-temperature environments;

2) Used for gas distribution, liquid bed orifice material;

3) Used for high-precision, highly reliable high-temperature filtering materials;

4) Used for high-pressure backwash oil filter.

Standard specifications and dimensionsHuahang

1) Standard material: SUS316L;

2) Standard specification size: 1200 * 1000 * 1.7mm;

3) The filtering accuracy is 2-300um.

Specific examplesHuahang

1) Precision filtration of various hydraulic and lubricating oils in the mechanical industry;

2) The filtration and purification of various polymer melts in the chemical fiber film industry, the filtration of various high-temperature and corrosive liquids in the petrochemical industry, and the filtration, washing and drying of materials in the pharmaceutical industry; 3) The application of gas homogenization in the powder industry, and the fluidization plate in the steel industry;

3) Sounders and other components in explosion-proof electrical appliances.

Shay

Shay