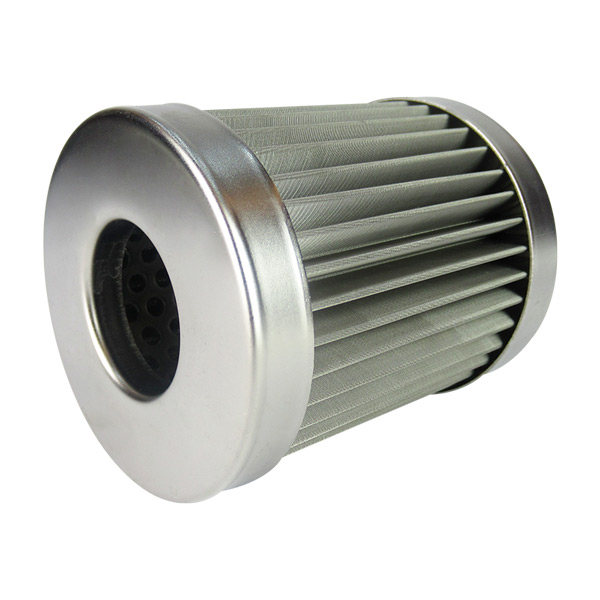

Custom Oil Filter Element 70x88

Product SpecificationsHuahang

Dimension |

70x88 |

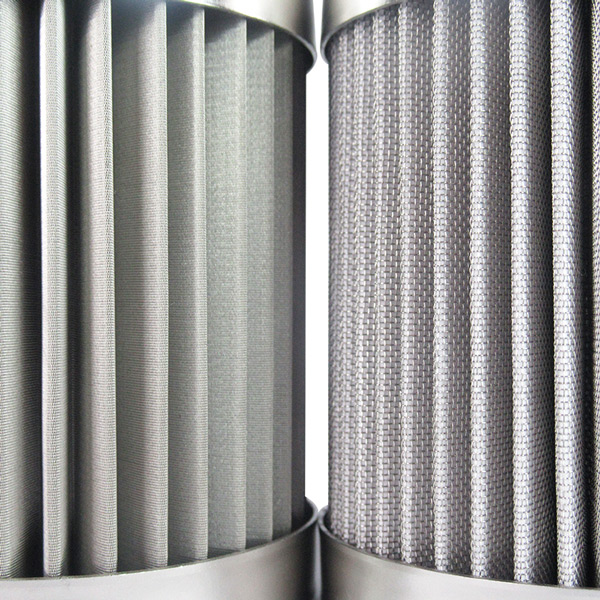

Filter layer |

Fiberglass/Stainless steel |

End caps |

304 |

Inner skeleton |

304 punched plate |

Sealing ring |

NBR |

APPLICATIONHuahang

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

NOTEHuahang

1. Electronics and pharmaceuticals: pre-treatment filtration of reverse osmosis water and deionized water, pre-treatment filtration of detergent and glucose.

2. Thermal power and nuclear power: purification of lubrication systems, speed control systems, bypass control systems, oil for gas turbines and boilers, purification of feedwater pumps, fans, and dust removal systems.

3. Mechanical processing equipment: lubrication systems and compressed air purification for papermaking machinery, mining machinery, injection molding machines, and large precision machinery, as well as dust recovery and filtration for tobacco processing equipment and spraying equipment.

Shay

Shay