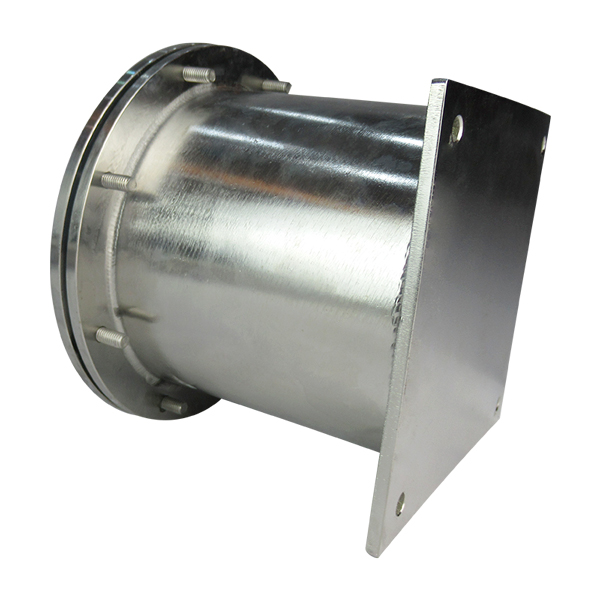

316L Stainless Steel Filter Element 170x175

Product SpecificationsHuahang

Type |

Stainlesss steel oil filter element |

Filter layer |

316L Stainless steel |

Dimension |

170x175 |

Interface |

With handle |

ADVANTAGESHuahang

1. Good filtration performance, suitable for 2-200 μ The filtration particle size of m can achieve uniform surface filtration performance;

2. Good corrosion resistance, heat resistance, pressure resistance, and wear resistance;

3. Uniform and precise filtration accuracy of stainless steel filter pores;

4. The stainless steel filter element has a large flow rate per unit area;

5. Stainless steel filter element is suitable for low and high temperature environments; After cleaning, it can be reused without replacement.

FAQ

HUAHANG

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Differences between 304 & 316 stainless steelHuahang

1. Chemical composition. 304 stainless steel is mainly composed of iron, chromium, and nickel, while 316 stainless steel contains an additional 2% to 3% molybdenum on this basis, which is the most significant difference between the two materials. forty-six

2. Corrosion resistance. 316 stainless steel performs better in resisting chloride corrosion due to the addition of molybdenum element, especially in chloride environments such as seawater or saline solutions. The corrosion resistance of 316 stainless steel is better than that of 304. thirteen

3. Strength. The strength of 316 stainless steel is slightly higher than that of 304. one

High temperature resistance. 316 stainless steel usually exhibits more stability and better heat resistance at high temperatures. thirty-five

4. Magnetism. 316 stainless steel is usually non-magnetic.

5. Application field. 304 stainless steel is widely used in the fields of kitchenware, building materials, and automotive components due to its good versatility and low cost. 316 stainless steel, due to its superior corrosion resistance, is commonly used in highly corrosive environments such as marine engineering, chemical equipment, medical devices, and implants

Shay

Shay