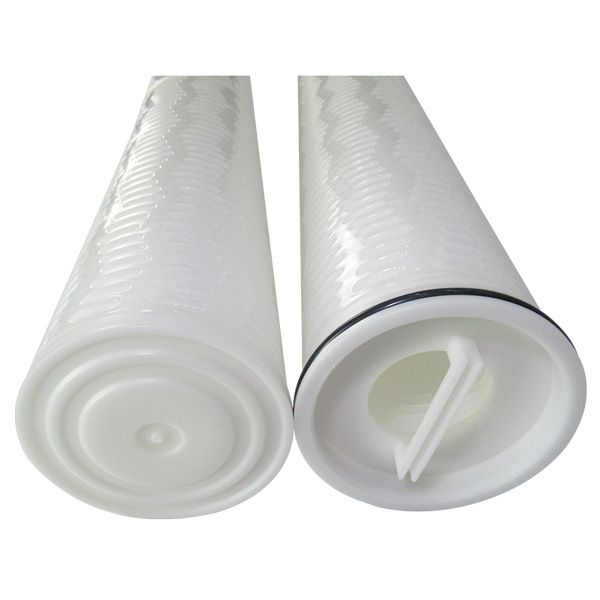

Stainless Steel Filter Element 70x120

Product SpecificationsHuahang

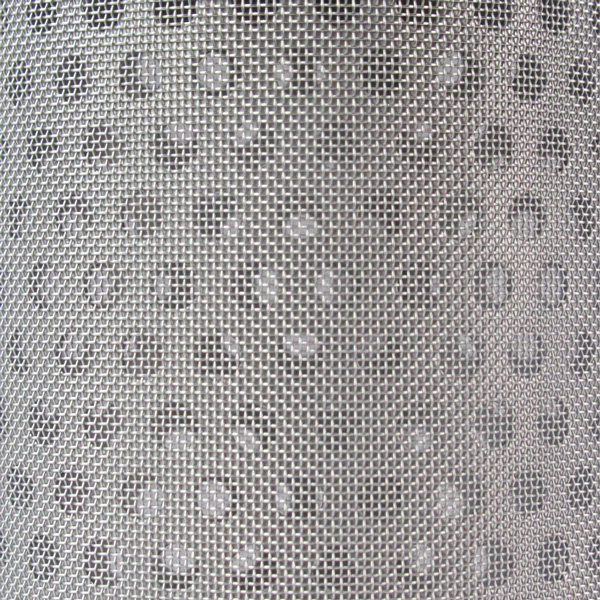

Filtration accuracy |

1~25μm

|

Filter layer |

Stainless steel |

Dimension |

70x120 |

Custom made |

Avaliable |

features

HUAhANG

Strong corrosion resistance: Stainless steel has good corrosion resistance, can work stably in various harsh environments, and can maintain its filtration performance for a long time.

Good high-temperature resistance: Stainless steel material has good high-temperature performance and can be used normally in high-temperature environments without softening or embrittlement.

High strength: Stainless steel material has high strength, can withstand large pressure and extrusion force, and is not easy to deform or break.

Lightweight: Compared to other materials of filters, stainless steel filters have a lighter weight and are easy to handle and replace.

Good cleaning performance: The stainless steel filter element has good cleaning performance, which can be repeatedly cleaned and reused, reducing the cost of use and maintenance.

Long lifespan: Due to the strong corrosion resistance, high temperature resistance, and high strength advantages of stainless steel material, its lifespan is relatively long, which can greatly reduce the frequency and cost of replacing filter elements.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Working principleHuahang

In the working principle of stainless steel filter cartridges, the main filtration mechanisms include surface filtration and deep filtration. Surface filtration means that impurities are fixed on the surface of the filtering medium, forming a filtration membrane or layer. This layer of filtration membrane continuously thickens but still retains the capture of impurities until the filter element needs to be cleaned or replaced. Deep filtration utilizes some impurities to penetrate the surface of the filtering medium and be captured inside, providing additional filtering capability to ensure that impurities do not pass through the filter element.

In order to extend the service life of stainless steel filter elements, backwashing or backflushing can be carried out, which is to remove accumulated impurities by reversing the cleaning solution or gas through the filter element. Backwashing removes impurities from the surface or inside of the filtering medium, restoring the filtering ability of the filter element. Regular maintenance and cleaning of stainless steel filters are key to maintaining their performance. Maintenance can include rinsing the filter with clean water or specific cleaning solutions to remove impurities and dirt.

1. Application environment: Firstly, determine which environment and medium the stainless steel filter element will be used in. For example, stainless steel 304 material is suitable for acid resistant environments, while 316 material is suitable for alkaline resistant environments. Select stainless steel materials based on the corrosive properties of the application environment. Some stainless steel alloys have stronger corrosion resistance and are suitable for media with high corrosiveness.

2. Filtering accuracy: Determine the filtering accuracy of the stainless steel filter element based on the filtering requirements. The filtration accuracy range of stainless steel filter element is 0.5-200um, and suitable filtration accuracy can be selected according to needs.

3. Filter Type: Choose the type of stainless steel filter according to specific application requirements. For example, high-quality fiber filters, high-density activated carbon and ID conversion filters, and FDF specific microcrystalline carbon composite filters are common choices.

4. Filter cartridge size: Select a stainless steel filter cartridge of appropriate size according to the requirements of the filtration equipment and system. Note that the inlet and outlet diameter should match the inlet diameter of the matching pump, generally consistent with the inlet pipeline diameter.

5. Nominal pressure and pore size: Determine the pressure level of the stainless steel filter element based on the highest possible pressure in the filtration pipeline, and consider the particle size of impurities to be intercepted. Select the pore size according to the process requirements of the medium flow.

6. Material and mechanical strength: Choose stainless steel material with appropriate mechanical strength to ensure that the filter element can withstand pressure and impact during operation.

7. Maintenance and cost-effectiveness: Consider the maintenance frequency and methods of stainless steel filter cartridges, as well as cost-effectiveness. Choose materials with good wear resistance and easy cleaning and maintenance to reduce maintenance costs.

2. Acid cleaning method

Dissolve potassium dichromate or crystals in water to 60 to 80 degrees, and slowly add concentrated sulfuric acid with a concentration of 94% until sufficient. Add slowly and stir. Add up to 1200 milliliters of potassium sulfate or completely dissolve, and the solution will appear dark red in color. At this time, the rate of adding concentrated sulfuric acid can be accelerated until it is completely added. If there are still undissolved crystals after adding concentrated sulfuric acid, they can be heated until dissolved. The function of cleaning solution is to remove general pollutants, grease, and metal particle impurities on the wall of stainless steel filter cartridge, and it can effectively kill the bacteria and microorganisms that grow on the filter cartridge and damage the heat source. If the filter element has been alkaline washed before, the alkaline solution must be washed first, otherwise fatty acids will precipitate and contaminate the filter element.

Shay

Shay