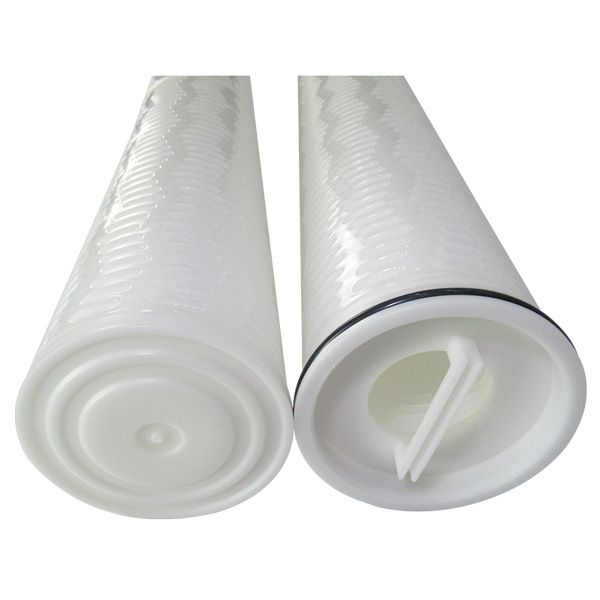

PP Melt Blown Filter RO.Zs 01-40-XK

Product SpecificationsHuahang

Part number |

RO.Zs 01-40-XK |

Media |

PP melt blown |

Sealing ring |

NBR |

End caps |

White PP |

Product FeaturesHuahang

Strong Porosity: The surface of the PP melt blown filter element is a network structure with uniform pore size distribution and high porosity, which can filter out large particle impurities and ensure smooth water flow.

High precision: The aperture size of the PP melt blown filter can be controlled by controlling the fiber diameter, heat, and temperature to achieve precision control, generally reaching 0.1-50 microns.

High temperature resistance, acid and alkali resistance: The PP melt blown filter element is made of polypropylene material, which has certain high temperature resistance, acid and alkali resistance properties and can adapt to different industrial filtration conditions.

Long lifespan: The PP melt blown filter element is made of a multi-layer mesh structure, which has high physical strength and durability, and a long service life.

Easy installation: The PP melt blown filter element adopts an end cap connection method, which is easy to install and can adapt to different filter models.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

application areaHuahang

1. Pharmaceutical industry: Pre filtration of various injections, medicinal liquids, and bottle washing water, as well as pre filtration of large infusion fluids, various antibiotics, and traditional Chinese medicine injections.

2. Electronic industry: Pre filtration of pure water and ultrapure water.

3. Petroleum and chemical industry: filtration of various organic solvents, acids, and alkalis, as well as filtration of oilfield water injection.

Shay

Shay