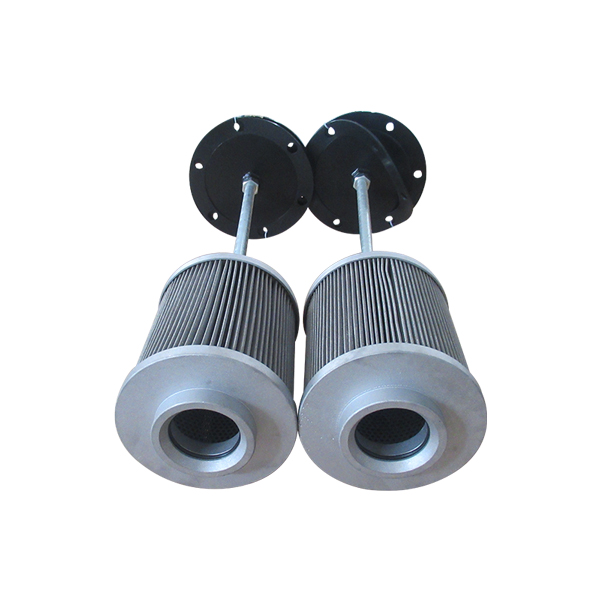

Suction Oil Filter XNJ-250×100-586-Y

Product SpecificationsHuahang

model |

Nominal flow rate (L/min) |

Filtration accuracy (μm) |

Drift diameter (mm) |

Initial pressure loss (MPa) |

Indicator (V/W) |

Weight (Kg) |

Model of element | |

(V) |

(A) |

|||||||

XNJ-25X*-Y/C |

25 |

|

20 |

≤0.007 |

24 36 220 |

2.5 2 1.5 0.25 |

0.7 |

JX-25 X* |

XNJ-40X*-Y/C |

40 |

20 |

0.8 |

JX-40 X* |

||||

XNJ-63X*-Y/C |

63 |

32 |

1.2 |

JX-63 X* |

||||

XNJ-100X*-Y/C |

100 |

32 |

1.4 |

JX-100 X* |

||||

XNJ-160X*-Y/C |

160 |

50 |

1.9 |

JX-160 X* |

||||

XNJ-250X*-Y/C |

250 |

50 |

2.1 |

JX-250 X* |

||||

XNJ-400X*-Y/C |

400 |

80 |

2.9 |

JX-400 X* |

||||

XNJ-630X*-Y/C |

630 |

80 |

4.5 |

JX-630 X* |

||||

XNJ-800X*-Y/C |

800 |

90 |

6.6 |

JX-800 X* |

||||

XNJ-1000X*-Y/C |

1000 |

90 |

6.9 |

JX-1000 X* |

||||

Product featuresHuahang

2. When cleaning or replacing the filter element, it is necessary to unscrew the screws on the installation flange and pull up the installation flange to clean or replace it.

3. Equipped with filter clogging signal device: When the filter is clogged by pollutants to a vacuum pressure of -0.018 MPa, the transmitter sends a switch signal (user external electrical signal). At this time, the filter should be replaced or cleaned in a timely manner to avoid oil pump suction and other faults.

4. Equipped with a bypass valve: When the filter element is blocked by pollutants to a vacuum pressure of -0.18 MPa, if it cannot be immediately stopped for cleaning or replacing the filter element, the bypass valve installed on the upper end of the filter element will automatically open (with an opening pressure of -0.02 MPa) to protect the normal operation of the oil pump

Shay

Shay