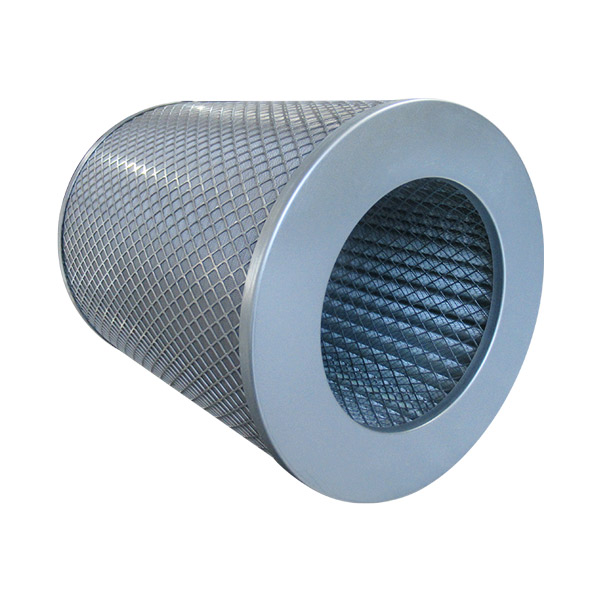

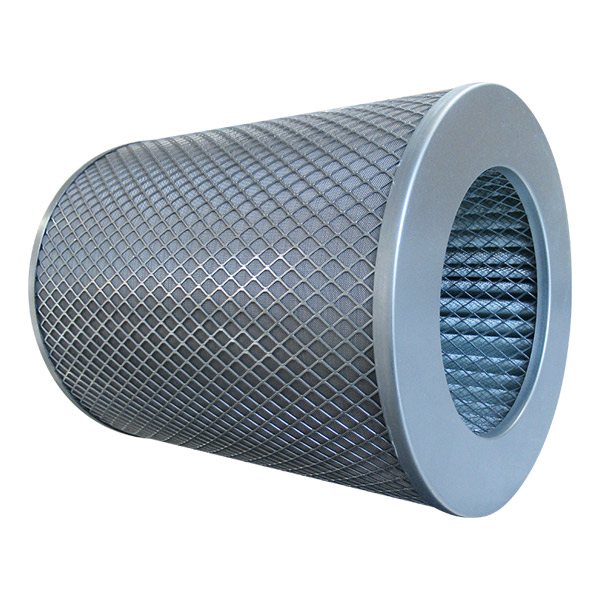

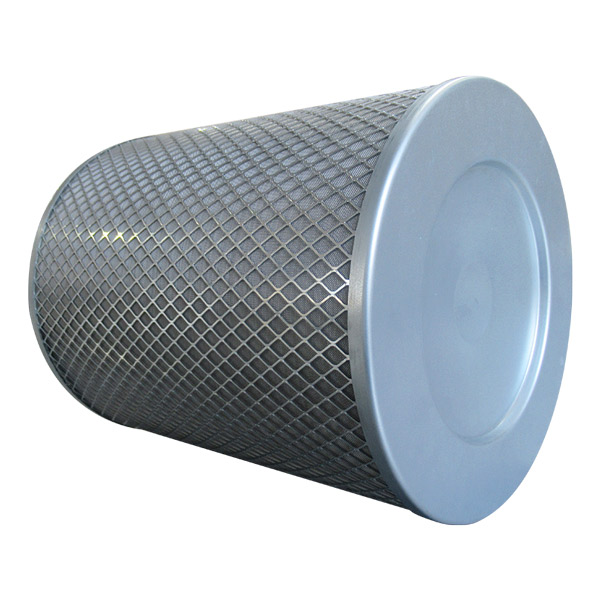

Oil Separator Filter Element 300x366

Product SpecificationsHuahang

Product Attribute |

Specification |

Dimension |

190x300x366 |

Media |

Composite parts |

End caps |

Carbon steel |

Skeleton |

Zinc infiltrated diamond mesh |

working principleHuahang

The air compressed from the head of the compressor host carries oil droplets of different sizes. Large oil droplets are easy to separate through the oil and gas separation tank, while small oil droplets (suspended) must be filtered through the micrometer sized fiberglass filter material of the oil and gas separation filter element. The correct selection of fiberglass diameter and thickness is an important factor in ensuring filtration efficiency. After the oil mist is intercepted, diffused, and polymerized by the filter material, small oil droplets quickly aggregate into large oil droplets, which pass through the filter layer under the action of aerodynamics and gravity and settle at the bottom of the filter element. These oils are continuously returned to the lubrication system through the inlet of the return pipe at the bottom of the filter element, allowing the compressor to discharge relatively pure and high-quality compressed air.

precaustionsHuahang

When the pressure difference between the two ends of the oil and gas separation filter reaches 0.15MPa, it should be replaced; When the pressure difference is 0, it indicates that the filter element is faulty or the airflow is short circuited. In this case, the filter element should also be replaced. The general replacement time is 3000-4000 hours. If the environment is poor, its usage time will be shortened.

When installing the return pipe, it must be ensured that the pipe is inserted into the bottom of the filter element. When replacing the oil and gas separator, pay attention to static discharge and connect the inner metal mesh with the outer shell of the oil drum.

Shay

Shay