0102030405

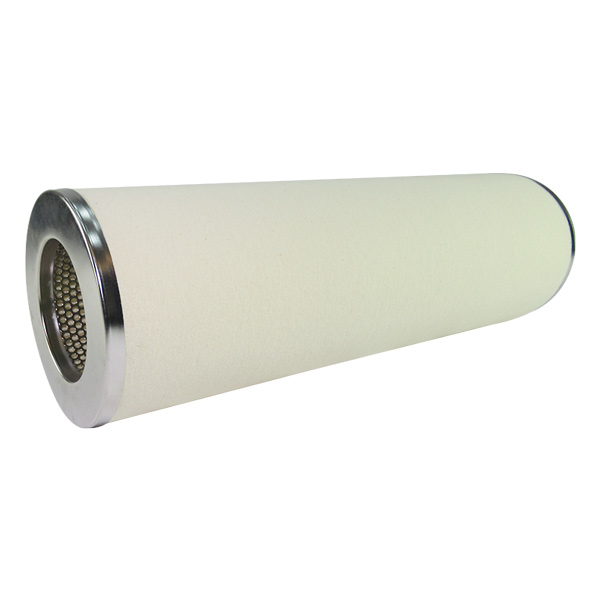

Custom Coalescer Filter Element 152x495

Product SpecificationsHuahang

Dimension |

152x495 |

Media |

Composite parts |

End caps |

304 |

Skeleton |

304 punched plate |

Maintenance methodsHuahang

1. The coalescence filter element is the core part of the filter, which is composed of special materials and is a vulnerable part that requires special protection and maintenance.

2. After the filter in the system has been working for a period of time, the hydraulic oil filter element in the filter has intercepted a certain amount of pollutants and impurities. At this time, the pressure increases, the flow rate gradually decreases, and the transmitter will remind the alarm. At this time, it is necessary to clean the impurities in the filter element in a timely manner and clean the filter element.

3. During the cleaning process of the filter element, we must be careful not to deform or damage the coalescence filter element. Otherwise, it cannot be used again to avoid affecting the filtration efficiency and causing damage to the entire system.

precaustionsHuahang

1. Proper Installation: A coalescence filter element should be installed in the correct direction of airflow. The inlet should be connected to the air supply source, and the outlet should be connected to the compressed air system. The filter element should also be installed securely to prevent any leaks or damage.

2. Filter Maintenance: Regular maintenance of the coalescence filter is crucial to its proper functioning. Cleaning or replacing the filter element when it begins to get clogged will improve its efficiency and prolong the life of the filter. It is also important to inspect the filter regularly for damage or signs of wear.

3. Proper Use: A coalescence filter element should not be exposed to high temperatures, chemicals, or corrosive materials. It is designed to operate in a clean, dry environment and should not be subject to any unnecessary vibrations or shocks.

4. Filter Element Replacement: When it is time to replace the filter element, it is important to use only high-quality replacement elements that are compatible with the original coalescence filter. A mismatched filter can lead to inefficient operation or worse, damage to the system.

In summary, a coalescence filter element is a critical component in many industrial filtration systems, used for removing water and oil mist from compressed air. Proper installation, maintenance, use, and replacement all play an important role in ensuring the efficient and effective performance of the filter element. By following these precautions, users can achieve optimal performance and prolong the life of their coalescence filter element.

.

Shay

Shay