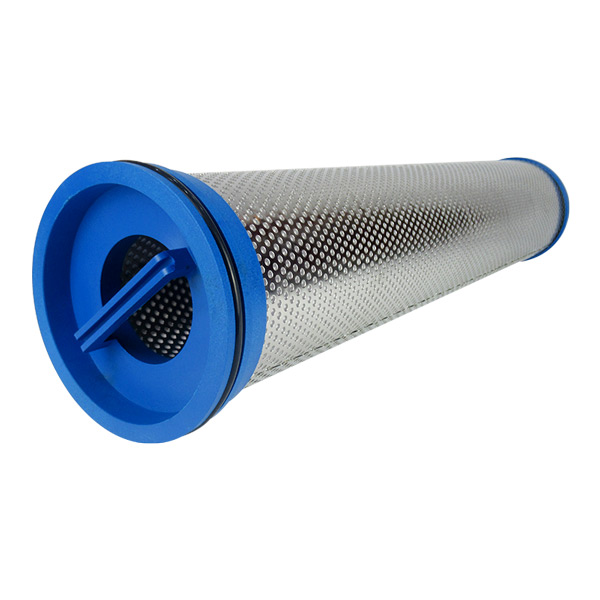

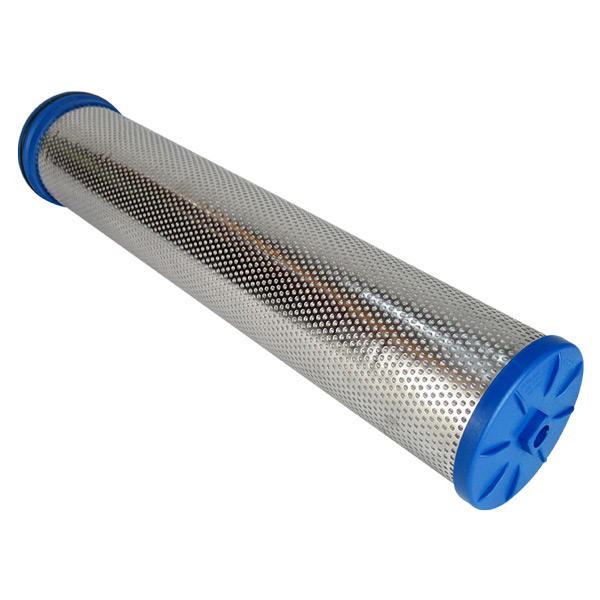

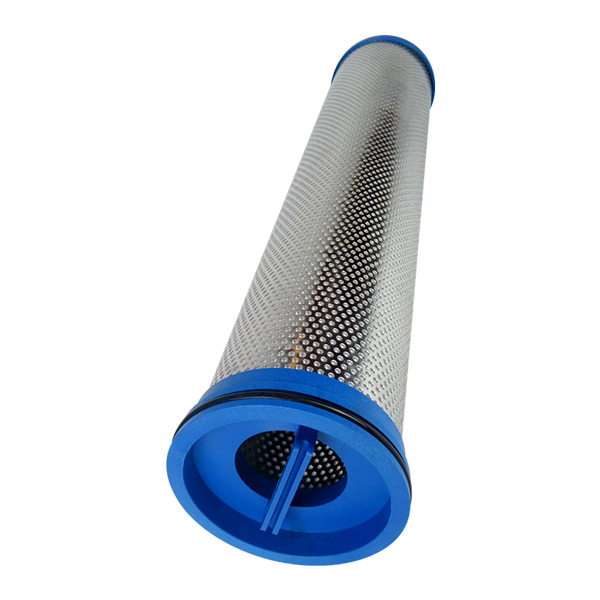

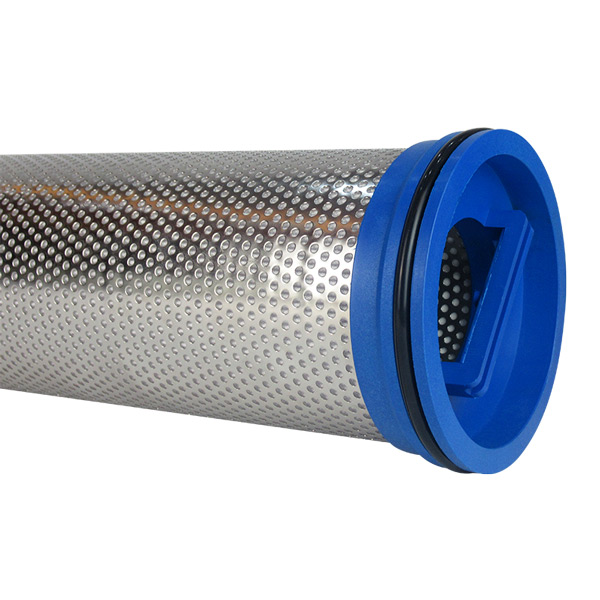

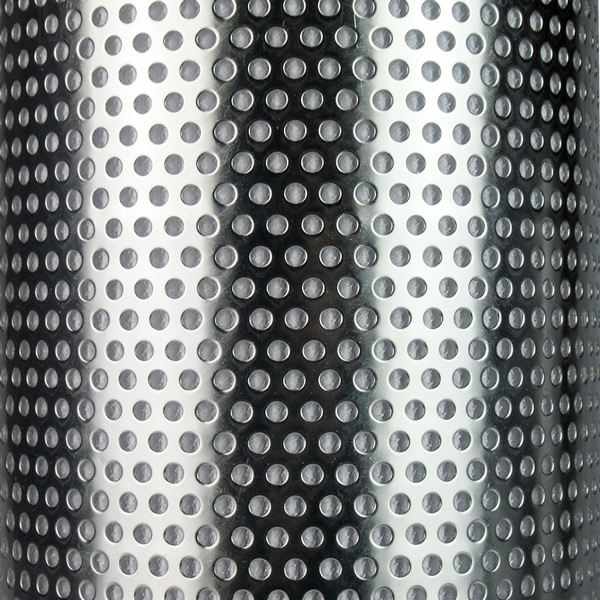

316 SS Gas Coalescer Filter 20x161

Product SpecificationsHuahang

Product Attribute |

Specification |

Dimension |

20x161x760 |

Media |

316 stainless steel |

End caps |

Plastic |

Sealing ring |

NBR |

Maintenance methodsHuahang

2. After the filter in the system has been working for a period of time, the hydraulic oil filter element in the filter has intercepted a certain amount of pollutants and impurities. At this time, the pressure increases, the flow rate gradually decreases, and the transmitter will remind the alarm. At this time, it is necessary to clean the impurities in the filter element in a timely manner and clean the filter element.

3. During the cleaning process of the filter element, we must be careful not to deform or damage the coalescence filter element. Otherwise, it cannot be used again to avoid affecting the filtration efficiency and causing damage to the entire system.

how to replacementHuahang

During this process, water usually spills out. Please prepare cleaning tools such as a water basin or towel:

1. Turn off the electroplated ball valve and pressure bucket ball valve;

2. Turn on the goose neck faucet to drain any remaining water from the pipeline;

3. After the water no longer flows out, use a filter housing wrench to open the filter housing containing the filter element;

4. Remove the old filter element and install a new filter element of the same specification;

5. Apply a lubricant such as Vaseline to the black O-ring above the filter housing, and then place the O-ring into the groove in the filter housing;

6. Tighten the filter housing vertically and try to avoid shifting the O-ring as much as possible;

7. Open the electroplated ball valve and pressure bucket ball valve.

Shay

Shay