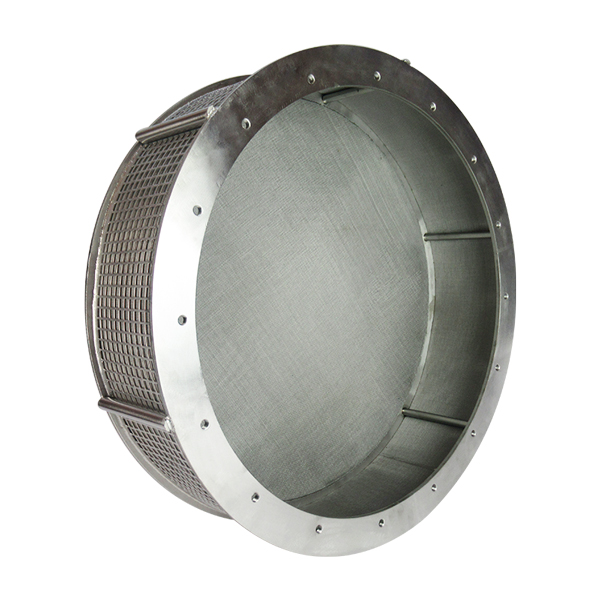

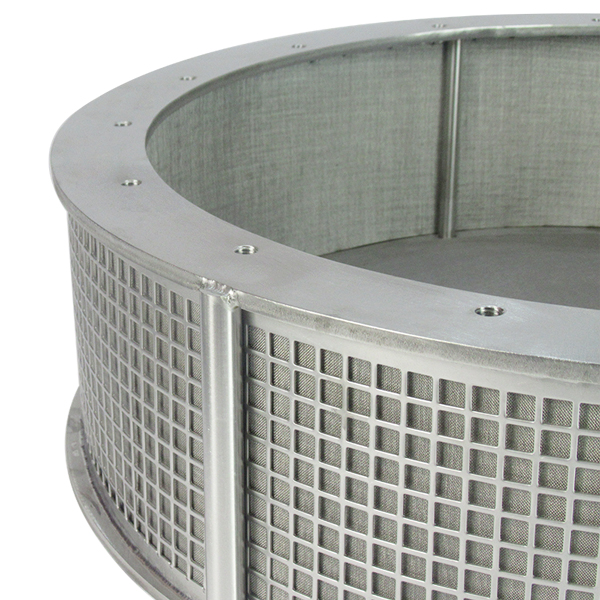

200μm Sintered Mesh Lim Element

Khoom SpecificationsHuahang

Hom | Sintered mesh lim caij |

Dimension | 530x624x161 ib |

Khoom siv | Stainless hlau mesh |

Pore loj | 200m ib |

Khoom ntaHuahang

1. Lub zog loj thiab zoo rigidity: nws muaj lub zog txhua yam thiab compressive zog, ua haujlwm zoo, vuam thiab sib dhos ua haujlwm, thiab siv tau yooj yim.

2. Uniform thiab ruaj khov precision: ua tau raws li qhov sib xws thiab kev ua haujlwm zoo ib yam rau txhua qhov kev lim dej, tsis muaj kev hloov pauv mesh loj thaum siv.

3. Siv dav hauv ntau qhov chaw: tuaj yeem siv rau kev pom hauv qhov kub thiab txias ntawm -200C txog 650C, nrog rau cov kua qaub thiab alkaline ib puag ncig.

4. Kev ua tau zoo ntawm kev tu: Cov nyhuv tshuaj tiv thaiv tam sim no zoo heev, tuaj yeem rov qab siv tau, thiab muaj lub neej ua haujlwm ntev (tuaj yeem ntxuav tau siv cov txheej txheem xws li dej countercurrent, lim, ultrasound, melting, ci, thiab lwm yam.)

Daim ntawv thovHuahang

1. Precision pom ntawm ntau yam hydraulic thiab lubricating roj hauv kev lag luam tshuab

2. Kev pom thiab purification ntawm ntau yam polymer melts nyob rau hauv cov tshuaj fiber ntau zaj duab xis kev lag luam, kev pom ntawm high-temperature thiab corrosive kua nyob rau hauv lub petrochemical kev lag luam, thiab pom, ntxuav, thiab ziab ntawm cov ntaub ntawv nyob rau hauv kev lag luam kws tshuaj.

3. Daim ntawv thov ntawm cov roj homogenization hauv kev lag luam hmoov thiab cov phaj fluidization hauv kev lag luam steel.

4. Lub splitter thiab lwm yam khoom siv hauv cov khoom siv hluav taws xob tawg.

5. Fluidization thiab ntom theem conveying tshuab rau thee txhaj tshuaj nyob rau hauv blast furnaces

6. Catalyst txhawb grille.

7. Cov khoom siv roj, cov khoom ua kua, thiab cov kua roj sib cais.

Shay

Shay