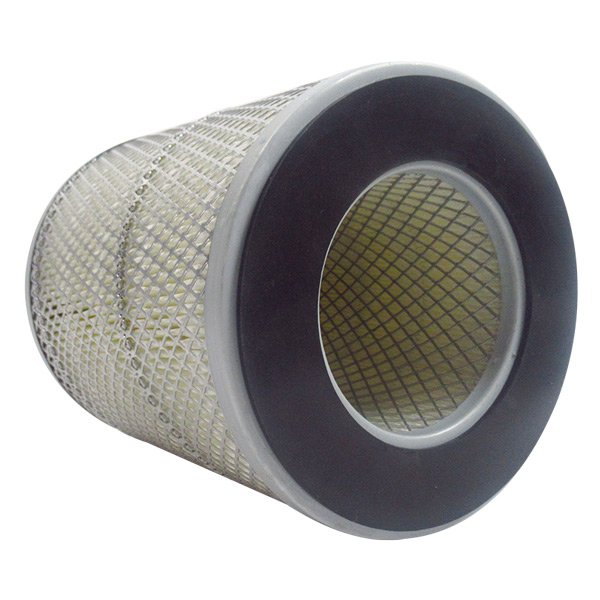

Custom Vacuum Air Filter Element 154x187

Product SpecificationsHuahang

Type |

Vacuum air filter cartridge |

Filter layer |

Polyester fabric |

Filtration efficiency |

99.9% |

Skeleton |

Stainless steel |

Custom made |

Avaliable |

Product FeaturesHuahang

Firstly, the filter element of the vacuum cleaner has excellent wear resistance. Due to the use of high-quality materials, they have characteristics such as bending resistance, wear resistance, compression resistance, moisture resistance, and softness without irritation, and can be reused without damage, thereby extending the service life of filter fabrics.

Secondly, the vacuum cleaner filter has a significant cleaning effect. These filters have high accuracy and can effectively block a large amount of dust particles, forming a barrier externally and effectively inhibiting bacterial growth and reproduction. Therefore, they improve cleaning efficiency and extend service life.

Another feature is the dual filtering function. By collecting very small or fine particles (such as bacteria and fibers) on non-woven fabrics, the vacuum cleaner filter screen undergoes a special treatment process for dual filtration, thereby more effectively cleaning the room.This design allows the vacuum cleaner to handle multiple types of dust and pollutants simultaneously.

preparation workHuahang

Firstly, understand the relevant parameters, construction, and installation precautions of the dust removal filter cartridge based on the technical drawings and instructions. Check the on-site installation environment to ensure that it is flat, clean, and dry, and to prevent dust and foreign objects from entering the filter cartridge. Check if the required number and specifications of accessories meet the requirements, and arrange suitable personnel for installation work. twelve

Assembly. Install the secondary ash cleaning system, inlet and outlet pipe components, flanges, and sealing gaskets on the prepared filter cartridge bracket. Install the flipping plate spraying device and fan, and check if the switch of the secondary ash cleaning system and fan is normal.

Lifting. Using lifting equipment, first lift the bracket into place and set up lifting points on the filter cartridge bracket. Hang the dust removal filter cylinder on the bracket with a lifting rope to ensure that the center of gravity is within a safe range. Personnel should coordinate and command below to ensure that the filter cartridge is not damaged by impact or friction.

Positioning. Use specialized tools or manually disassemble the flange to adjust the filter cartridge in place, aligning the inlet and outlet flanges with the gas pipe. Correct the filter cartridge shaft, flange, and flange cover and tighten the bolts to ensure that the filter cartridge is securely installed.

Fixed. According to design requirements, technical standards, and safety regulations, fix the filter cartridge and bracket, and check for any air leakage at the connections. Complete the wiring and debugging work of the positive and negative control lines of the filter cartridge and the secondary ash cleaning system. Conduct a comprehensive inspection of the installation work to ensure that the filter cartridge is installed intact, without any leaks, looseness, or gaps.

Shay

Shay