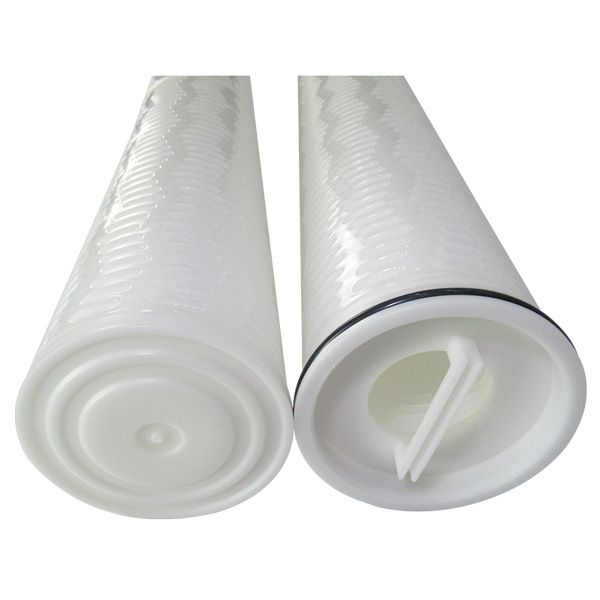

Custom Oil Filter Element 85x57

Product SpecificationsHuahang

End caps |

Aluminum |

Filter layer |

Stainless steel mesh |

Dimension |

85x57 |

Inner Skeleton |

304 punched plate |

faqHuahang

1、 Material standards

The main materials for oil filter cartridges are cellulose, polypropylene, polyamide, stainless steel, etc. These materials should comply with relevant national standards, for example, cellulose should meet the requirements specified in GB/T20582-2006.

2、 Production process standards

The production process of oil filter cartridges includes textile, pressing, and assembly processes. Among them, the textile production process should comply with the relevant provisions in GB/T 5270-2005; The pressing production process should comply with the relevant provisions in GB/T 17656-2018; The assembly production process should comply with the relevant provisions in GB/T 25153-2010.

3、 Performance testing standards

The performance testing of oil filter elements includes resistance testing, dust capacity testing, service life testing, etc. Among them, the resistance test should comply with the relevant provisions in GB/T13310-2008; The dust capacity test should comply with the relevant provisions in GB/T14295-2012; The service life test should comply with the relevant provisions in GB/T25152-2010.

4、 Quality inspection standards

The quality inspection standards for oil filter cartridges include general appearance inspection, dimensional inspection, filtration efficiency inspection, etc. Among them, the general appearance inspection should comply with the relevant provisions in GB/T25154-2010; Dimensional inspection should comply with the relevant provisions in GB/T14727-2013; The filtration efficiency test should comply with the relevant provisions in GB/T25152-2010.

1、 Material standards

The main materials for oil filter cartridges are cellulose, polypropylene, polyamide, stainless steel, etc. These materials should comply with relevant national standards, for example, cellulose should meet the requirements specified in GB/T20582-2006.

2、 Production process standards

The production process of oil filter cartridges includes textile, pressing, and assembly processes. Among them, the textile production process should comply with the relevant provisions in GB/T 5270-2005; The pressing production process should comply with the relevant provisions in GB/T 17656-2018; The assembly production process should comply with the relevant provisions in GB/T 25153-2010.

3、 Performance testing standards

The performance testing of oil filter elements includes resistance testing, dust capacity testing, service life testing, etc. Among them, the resistance test should comply with the relevant provisions in GB/T13310-2008; The dust capacity test should comply with the relevant provisions in GB/T14295-2012; The service life test should comply with the relevant provisions in GB/T25152-2010.

4、 Quality inspection standards

The quality inspection standards for oil filter cartridges include general appearance inspection, dimensional inspection, filtration efficiency inspection, etc. Among them, the general appearance inspection should comply with the relevant provisions in GB/T25154-2010; Dimensional inspection should comply with the relevant provisions in GB/T14727-2013; The filtration efficiency test should comply with the relevant provisions in GB/T25152-2010.

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Classification And applicationHuahang

Hydraulic oil filter element for oil suction pipeline: The oil suction pipeline (oil tank - hydraulic pump inlet) or directly installing the oil suction filter element in the oil tank is a necessary measure to protect the hydraulic pump, and its accuracy is generally 100-180 degrees μ m. Determine based on the different self suction capabilities of the pump, as excessive flow resistance leads to cavitation of the hydraulic pump.

Pressure Line Hydraulic Oil Filter Element: The pressure line oil filter element is not only used to protect downstream components, but also serves as the main oil filter to ensure system oil contamination. Through its efficient purification of the oil, it also provides good protection for hydraulic pumps, with a filtration accuracy of 5-10 μ m. The filter is subjected to high pressure and vibration, and the allowable pressure difference of the oil filter element in the pressure pipeline ranges from 0.3 to 0.7 MPa according to different pressure levels. As a pressure pipeline oil filter for ground equipment, considering both cost and installation space, the greater the potential.

Hydraulic oil filter element in the return oil pipeline: Various pollutants such as abrasives generated by various components during operation can be intercepted by setting the return oil pipeline oil filter to avoid returning to the oil tank and being sucked in by the hydraulic pump again. The allowable pressure difference of the return oil pipeline oil filter is within the range of 0.3-0.5MPa according to different pressure levels.

Shay

Shay