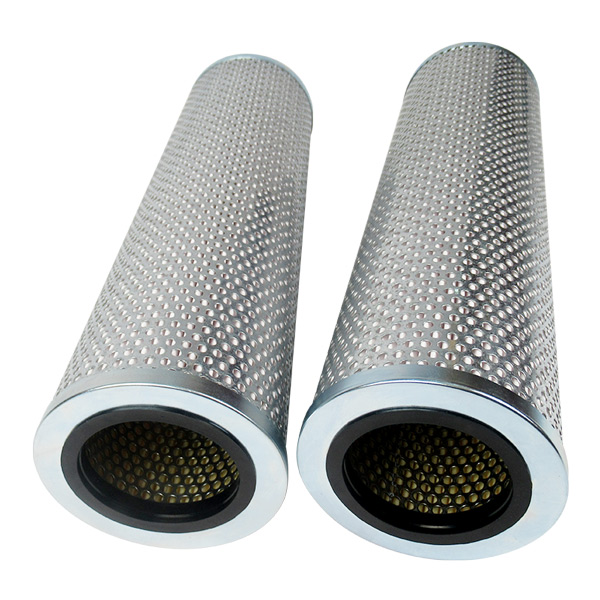

Custom Oil Filter Element 132.5x460

Product SpecificationsHuahang

Dimension |

132.5x460 |

Filter layer |

Stainless steel/Fiberglass |

Skeleton |

Carbon steel punched plate |

End caps |

Carbon steel |

MaterialHuahang

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

precautiousHuahang

Shay

Shay