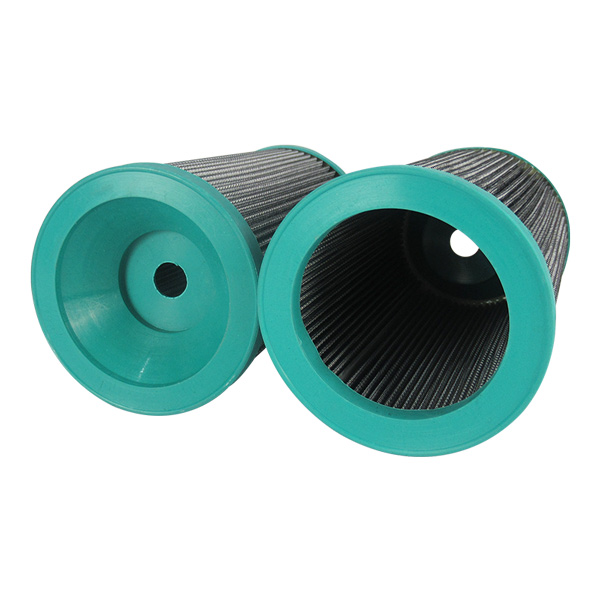

Replace Oil Filter 937853Q

Product SpecificationsHuahang

Part number |

937853Q |

Filter layer |

Fiberglass |

Filtration accuracy |

1~50μm |

Working temperature |

100℃ |

RALATED PART NUMBERHuahang

Metal material. Oil filters made of materials such as stainless steel metal mesh, metal woven mesh, sintered mesh, etc. have good corrosion resistance and high temperature performance, making them suitable for high-pressure and high-temperature environments.

Paper material. Including fiberglass filter paper, chemical fiber filter paper, wood pulp filter paper, etc., paper oil filter cartridges are inexpensive but require frequent replacement.

Metal fiber material. The filter element made of metal fibers has high strength, high adhesion, and high temperature resistance, making it suitable for high-pressure and high-temperature hydraulic systems.

Ceramic material. The filter element made of ceramic material has excellent corrosion resistance and high temperature resistance, and is suitable for filtering acidic, alkaline, and high-temperature liquids.

Polymer materials. Materials such as nylon cloth and porous materials treated with phenolic resin are used to manufacture filter cartridges with high-precision filtration performance

1. Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

Special design can achieve an effective filtration area of 100%;

2. Each component adopts a seamless fusion method, which solves many problems that originally existed in use and ensures safety;

3. The design adopts a metal folding frame, which can be reused and replaced;

4. The density of the filter material shows an increasing structure, achieving high efficiency, low resistance, and large dust capacity;

HOW TO CHOOSE OIL FILTERHuahang

1. Inlet and outlet diameter

In principle, the inlet and outlet diameter of the stainless steel filter element should not be smaller than the inlet diameter of the matching pump, generally consistent with the inlet pipeline diameter.

2. Selection of nominal pressure and aperture mesh

Determine the pressure level of the stainless steel filter element based on the maximum pressure that may occur in the filtration pipeline, mainly considering the particle size of impurities to be intercepted, according to the process requirements of the medium flow.

3. Filter Element Material

The material of stainless steel filter cartridges is generally chosen to be the same as the material of the connected process pipeline. For different service conditions, cast iron, carbon steel, low alloy steel, or stainless steel filter cartridges can be considered.

4. Filter element resistance loss

Calculate the pressure loss based on the actual medium. The installation of filter elements should not affect the normal operation of the system. The number of filter elements can be increased according to the situation to reduce the pressure loss.

Shay

Shay