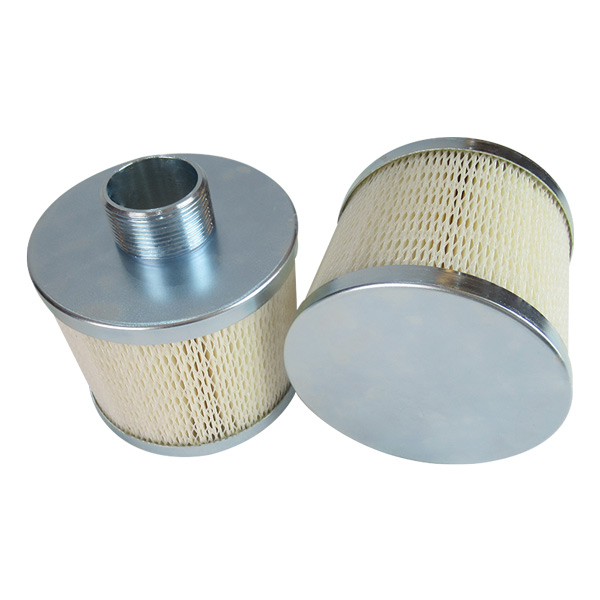

Paper Air Filter Cartridge 125x130

Product SpecificationsHuahang

Dimension |

125x130 |

Filter layer |

Paper |

Interface |

G1 1-2 External thread |

Outer Skeleton |

Plastic mesh |

End caps |

Carbon steel |

Product FeaturesHuahang

1. High filtration efficiency and low dust transmission rate

2. Compact structure, can be installed in any direction

3. Convenient maintenance, which can save time and costs

4. Low quality and low cost

maintainHuahang

1. The filter element is the core component of a filter, made of special materials and is a vulnerable part that requires special maintenance and upkeep;

2. After a long period of operation, the filter element has intercepted a certain amount of impurities, which can lead to an increase in pressure and a decrease in flow rate. At this time, it is necessary to clean it in a timely manner;

3. When cleaning, be sure not to deform or damage the filter element.

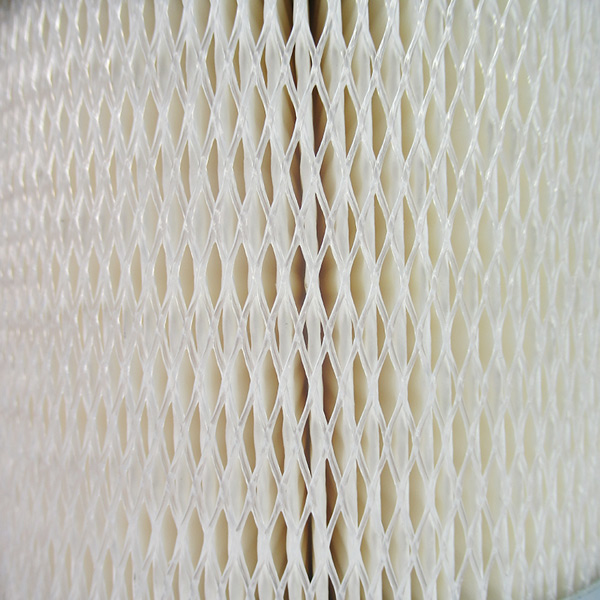

The filter paper in the equipment is also one of the key factors. High quality filter equipment usually uses ultra-fine fiber paper filled with synthetic resin, which can effectively filter impurities and has strong pollution retention capacity. According to relevant statistics, a passenger car with an output power of 180 kilowatts can filter out approximately 1.5 kilograms of impurities during its 30000 kilometer journey. In addition, the equipment also has a high requirement for the strength of the filter paper. Due to the high air flow rate, the strength of the filter paper can resist strong airflow, ensure filtration efficiency, and extend the service life of the equipment

Shay

Shay